how to heat treat carbon steel Heat treatment processes for steel – ispatguru

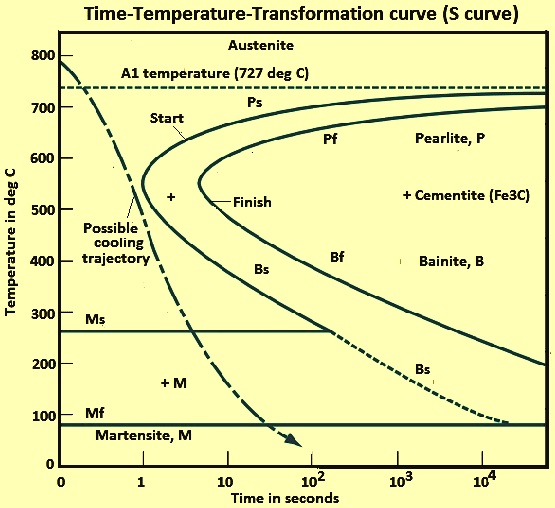

In the world of metallurgy, heat treatment is a crucial process that involves the alteration of physical and sometimes even chemical properties of a metal, usually through the application of heat and cooling methods. Steel is one such metal that undergoes various types of heat treatment to achieve desirable changes in its mechanical and physical properties such as hardness, ductility, toughness, and strength. The most common types of heat treatment include annealing, normalizing, quenching, tempering, and case hardening. Each of these processes has a specific purpose and is employed depending on the intended use of the steel product. Annealing is a heat treatment process that involves heating steel to a specific temperature and holding it there for a specific amount of time before slowly cooling it down. It is used to reduce hardness and increase ductility, making the steel easier to work with or shape into the desired form. After annealing, the steel also becomes less brittle and less prone to cracking. Normalizing, on the other hand, involves heating the steel to a specific temperature and cooling it in still air. This process is done to improve the toughness and strength of the steel, making it more resistant to wear and tear. The resulting steel has better machinability and can be easily welded without the risk of cracking. Quenching is a process that involves heating steel to a high temperature and then rapidly cooling it in water or oil. This process results in a hardening of the steel due to the rapid cooling rate. However, this process may also cause the steel to become brittle, which can be rectified through tempering. Tempering is a heat treatment process that involves reheating quenched steel to a specific temperature and then slowly cooling it. This process helps to reduce the brittleness and improve the toughness of the steel. Tempering also reduces the overall hardness of the steel and can help to alleviate any internal stress points. Finally, case hardening is a process used to harden only the surface of the steel. This process involves heating the steel in a carbon-rich environment, forming a thin layer of hardened steel on the outside of the product. This process results in a product that is wear-resistant while maintaining ductility and toughness. In conclusion, heat treatment is a vital process for ensuring that different types of steel are optimized for their intended uses. The five types of heat treatments discussed have their unique advantages and disadvantages, and manufacturers use each selectively depending on the specific steel application. By utilizing the appropriate heat treatment process, manufacturers can produce high-quality steel products that meet the needs of their customers.

If you are searching about Types of Heat Treatment of Steel and What is Heat Treatment? - Win Win you’ve visit to the right place. We have 5 Images about Types of Heat Treatment of Steel and What is Heat Treatment? - Win Win like How To Heat Treat Carbon Steel (1084/1075/15N20/5160…Simple Carbon, Types of Heat Treatment of Steel and What is Heat Treatment? - Win Win and also How To Heat Treat 1084 Carbon Steel? Update - Achievetampabay.org. Here you go:

Types Of Heat Treatment Of Steel And What Is Heat Treatment? - Win Win

www.win-therm.com.myhardening steel therm

www.win-therm.com.myhardening steel therm

How To Heat Treat 1084 Carbon Steel? Update - Achievetampabay.org

achievetampabay.orgHow To Heat Treat Carbon Steel (1084/1075/15N20/5160…Simple Carbon

achievetampabay.orgHow To Heat Treat Carbon Steel (1084/1075/15N20/5160…Simple Carbon

nordicedge.com.auHeat Treatment Processes For Steel – IspatGuru

nordicedge.com.auHeat Treatment Processes For Steel – IspatGuru

www.ispatguru.comispatguru

www.ispatguru.comispatguru

How To Easily Heat Treat And Temper 1095 High Carbon Steel. Www

www.pinterest.comhardening 1095 knifemaking treating

www.pinterest.comhardening 1095 knifemaking treating

How to easily heat treat and temper 1095 high carbon steel. www. Hardening 1095 knifemaking treating. How to heat treat carbon steel (1084/1075/15n20/5160…simple carbon